Most industries have realized that more will require to sustain their growth and development. It is not enough to build better manufacturing plants; it will also need to look for more efficient management. Artificial intelligence is one solution to this problem.

Systems having the processing power to evaluate information and discover solutions in an automated and timely manner can aid decision-making and ensure better results.

Table of Contents

Artificial Intelligence

AI, artificial intelligence, is a science that seeks to build systems endowed with the ability to reason – a characteristic. Until then, inherent only to human beings – so that they can deal with problems in an automated way.

You must have seen movies, for example. That explore stories with intelligent robots that interact with humans and solve problems quickly.

Our reality is far from Hollywood’s imagination. However, there are already systems capable of performing a series of tasks. And can also use this software to improve the Industry’s results.

Importance Of Artificial Intelligence In Today’s Industries

With the appearance of Industries 4.0 and new technologies, there is no more room for large, labor-based production plants. As a result, more and more large sectors are investing in automating the manufacture of their products.

In this context, artificial intelligence assumes a central role. And with the automation of the entire production chain, a series of impacts will expect on the new Industries. Check out some of them in the following topics.

More Transparency

With artificial intelligence linked to all points of a production plant through the internet of things, it is possible to obtain more transparency throughout the system.

It is possible to check in real-time what is happening in the production plant. Monitor all the processes in progress, and make any necessary changes.

Intelligent systems allow you to program specific actions according to the information collected. Such as increasing or decreasing production and using other materials.

Quick Answer

The market changes constantly, and for your company to remain relevant, it must be able to adapt to changes efficiently. Artificial intelligence systems can work with internal and external data. Crossing information to make strategic decisions independently.

For example, by identifying a decrease in demand for a particular product by analyzing market information. It is possible to decrease production speed to avoid excess inventory immediately.

Quality Of Artistry

One of the significant impacts of automation in Industries 4.0 is the decrease in the need for a workforce since manufacturing can rely on robots for production.

However, people trained to maintain this equipment. Manage its software and keep the factory running are essential.

Predict Behaviors

Large companies have already observed that they can strategically use these systems to predict their customers’ behaviors, such as preferences and demands.

Artificial intelligence systems can also predict market behavior, identifying risks or opportunities for manufacturing, such as a drop or increase in demand due to a specific variable.

Assist In Strategic Decision Making

Making decisions quickly and in the best possible way has been one of the biggest challenges for companies — and it’s easy to understand why. With globalization and ease of import and export, market competition has increased significantly.

In this scenario, with a wide range of suppliers, a wrong decision can cause your company to lose market share and face many difficulties in recovering.

In this sense, it is possible to use artificial intelligence software to mine data and search for insights and relevant information that collaborate for quick and much safer decision-making.

Automate Production

One of the main goals of industries looking for AI systems is to automate processes or be a part of them. Today, several tools on the market can help with this issue.

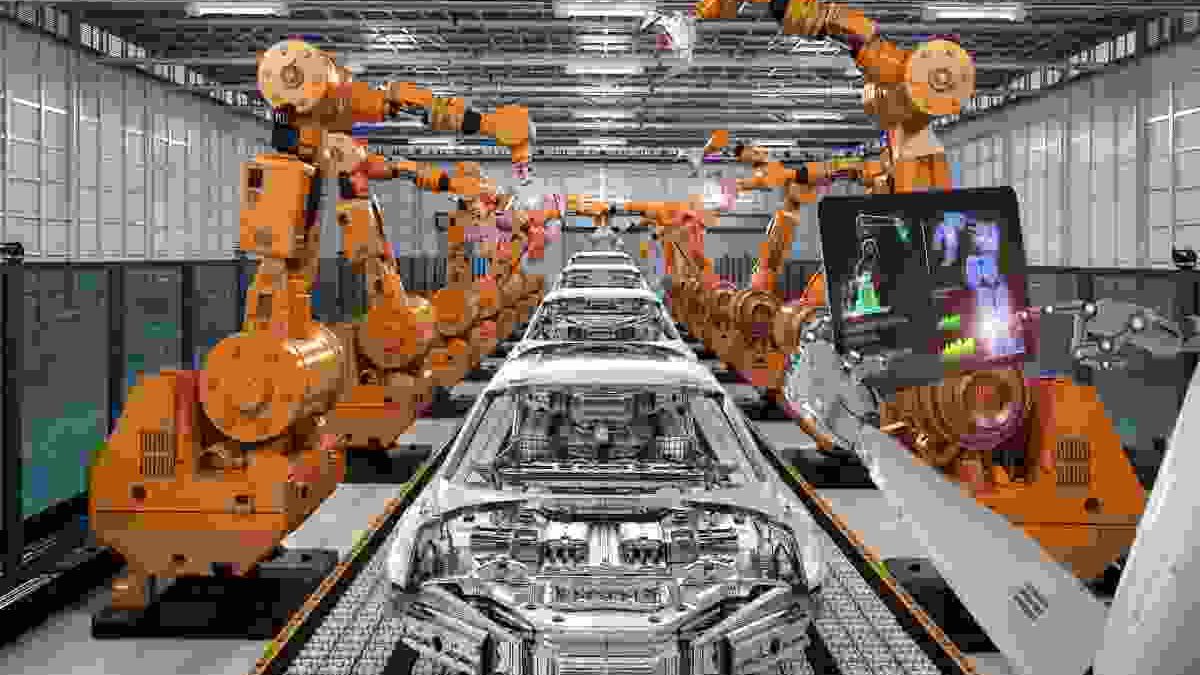

The most common use is investing in robotizing part of the production. For example, robots are more common in the automobile industry, using this resource in production lines.

However, with the increasingly improved machine learning techniques, the internet of things, and artificial intelligence, we will increasingly see factories using robots in their production processes.

Minimize Production Costs

One of the indirect applications of AI is related to cost minimization. By adapting production according to demand, tracing innovative routes, and controlling inventories efficiently, AI systems collaborate to reduce operating expenses.

Several costs within manufacturing go unnoticed in managers’ eyes, but that can will identify and avoided by AI systems.

Artificial intelligence is already a reality in several industries, and the trend is for it to become increasingly common. To maintain competitiveness, it is necessary, from now on, to seek solutions that prepare manufacturing for the implementation of these systems.